The industrial-grade 3D Printing Machine is characterized by a large printing size, high precision, and fast speed. It can fulfill the high-precision demands of industrial production for parts. It can employ multiple technologies like SLS and SLM and is frequently used to manufacture parts and molds in fields such as aerospace, automobiles, and medical treatment.

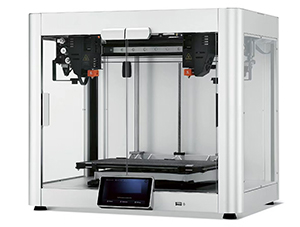

The desktop-level 3D Printing Machine is of relatively compact size and is suitable for individuals, small studios, or educational institutions. It mainly utilizes FDM technology and is capable of printing small items that do not have extremely high precision requirements, such as toys, models, and creative ornaments.

ornaments.

MOMAKING's industrial-grade 3D Printing Machine can print extremely fine details,

thoroughly meeting the strict requirements of the precision manufacturing industry and effectively guaranteeing the high-precision level of finished products.

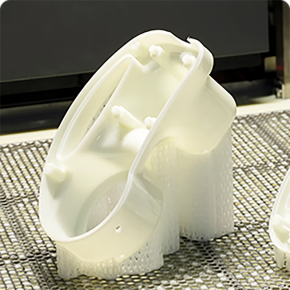

MOMAKING's industrial-grade 3D Printing Machine can print extremely fine details, thoroughly meeting the strict requirements of the precision manufacturing industry and effectively guaranteeing the high-precision level of finished products.

MOMAKING's industrial-grade 3D Printing Machine can handle a larger printing volume and is able to print large parts or multiple parts simultaneously, making it highly suitable for batch production and large-scale equipment manufacturing scenarios.

They support a variety of high-performance engineering resins and thus can be widely applied in many crucial fields such as aerospace, automobile manufacturing, and medical equipment.

MOMAKING's industrial-grade 3D printing machines not only possess excellent high precision, an extremely large molding size, and wide material applicability, but also have stable and reliable performance. Whether it is for processing complex parts or manufacturing precise medical devices, the industrial-grade 3D printing machines can provide excellent printing results.

SLA

Resin Materials

SLS

White Nylon Materials

MJF

Black Nylon Materials

SLM

Metal Materials

DLP

Red Wax Materials

| Material Name | Color | Printing Technology | Lead Time | Features |

| Imported Photosensitive Resin | White | SLA | 24H | High precision, smooth surface, suitable for both appearance and structural, assembly, and functional verification parts |

| Semi-Transparent Photosensitive Resin | Semi-Transparent | SLA | 48H | Smooth surface, strong detail expression, excellent waterproof and dimensional stability |

| Transparent Photosensitive Resin | Transparent | SLA | 72H | High transparency, crystal clear color, high brightness, low water absorption |

| High Temperature Resistant (70°C) Photosensitive Resin | Yellowish | SLA | 24H | Excellent high temperature resistance, suitable for hand sample products with high temperature requirements |

| High Temperature Resistant (100°C) Photosensitive Resin | Beige | SLA | 48H | Excellent high temperature resistance, suitable for hand sample products with high temperature requirements |

| Nylon | Off-White | SLS | 72H | Excellent toughness, abrasion resistance, widely used in various industries |

| High Performance Nylon | Black | MJF | 72H | Very high strength, good heat resistance, suitable for small batch parts |

| Red Wax | Peach | DLP | 24H | High precision, fine printed model pattern, smooth surface texture |

| Stainless Steel-316L | Natural Color | SLM | 3-5 Days | High tensile strength, temperature resistance, and corrosion resistance |

| Mold Steel-MS1 | Natural Color | SLM | 3-5 Days | High hardness, wear resistance, high quenching transparency, high heat fatigue resistance |

| Aluminum Alloy ALSi10Mg | Natural Color | SLM | 3-5 Days | High machinability and ductility, good strength-to-weight ratio |

| Titanium Alloy TC4 | Natural Color | SLM | 4-7 Days | Lightweight, high strength, good toughness, corrosion resistance |

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by depositing successive layers of material under computer control. This technology allows the creation of complex shapes and geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

3D printing involves a few main steps: first, a digital model of the object is created using computer-aided design (CAD) software. Then, this model is sliced into thin horizontal layers, and the 3D printer builds the object layer by layer, following the instructions from the digital model.

3D printing has a wide range of applications across various industries, including prototyping, product development, customization, rapid manufacturing, and even healthcare, where it's used for creating medical implants and prosthetics.

Upload your 3D file to instantly receive the best price

Your data is kept strictly confidential.