Injection molds enable high-precision product shaping, apt for plastic items with intricate forms and precise dimensions. Mold design and manufacturing precision directly impacts product quality; hence, injection molds demand refined precision machining. Their output shows excellent consistency and stability, with minimal errors, fitting well for high-standard component production.

Injection molds, featuring high precision, are great for mass production. They create multiple products in a short cycle, guaranteeing high efficiency. Thus, injection molding becomes the main way for large-scale plastic production and is widely applied in industries. Thanks to a considerable automation degree, they can couple with robotic arms and conveyor belts for efficient unmanned or lightly manned operation.

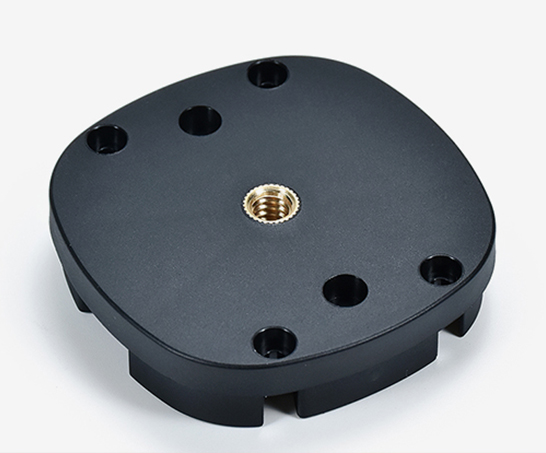

Injection molds can be diversely and customarily designed to meet specific demands, enabling the production of products with various shapes and complex structures. Through precise mold cavity and core design, complex formations like inserts, threads, and gears can be achieved.

Injection molds, typically made of high-strength steel and undergoing heat treatment and other procedures, possess excellent qualities such as wear, high-temperature, and corrosion resistance. They're fit for long-term use with a long service life. Based on materials and operating conditions, a mold can yield tens of thousands or even hundreds of thousands of injection molded products.

Injection Molding

Overmolding Injection

Insert Molding

Two-Color Injection Molding

Upload your 3D file to instantly receive the best price

Your data is kept strictly confidential.