For parts with extremely strict requirements for dimensional accuracy, shape accuracy and surface roughness, CNC machining is undoubtedly the best choice. CNC machining has the ability to accurately achieve the predetermined accuracy targets.

For parts with complex curved surfaces, special-shaped contours or intricate internal structures, CNC machining can easily plan the tool path by means of programming and then accurately create complex shapes.

When enterprises face various customized demands from different customers and the types of processed parts need to be frequently changed, CNC machining shows its flexibility advantage.

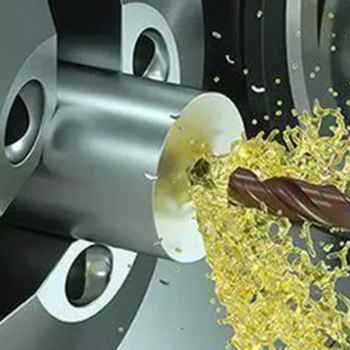

CNC machining precisely controls the movement of the machine tool through computer programs, accurately sets the tool path and cutting parameters. The positioning accuracy reaches ±0.005 - ±0.01mm, and the repeat positioning accuracy reaches ±0.002 - ±0.005mm, ensuring accurate machining without errors.

CNC machine tools intelligently optimize the spindle speed and feed rate according to the material and processing requirements, and multiple axes work in coordination, significantly reducing the processing time and showing high-efficiency advantages in batch production.

When processing prototypes, the program precisely controls the cutting speed and feed amount of the tool, which can be flexibly adjusted as needed to reduce frictional heat generation, prevent material from deforming due to overheating, and ensure the dimensional and appearance quality. The coolant runs simultaneously to eliminate the influence of metal thermal expansion and stabilize the accuracy of each part.

CNC machining accurately plans the machining allowance according to the prototype design, avoiding strength reduction caused by excessive cutting. Unlike manual machining which generates a large amount of residual stress due to uneven cutting force and weakens the strength, CNC machining makes the cutting force evenly distributed, reduces the residual stress and endows the prototype with reliable strength.

CNC Turning

3-axis, 4-axis, and full 5-axis machining

CNC Drilling

3-axis, 4-axis, and full 5-axis machining

CNC Milling

3-axis, 4-axis, and full 5-axis machining

| Aluminum Alloy | Aluminum Alloy 6061 | Aluminum Alloy 5052 | Aluminum Alloy 2A12 | Aluminum Alloy 7075 | - | - | - | - |

| Stainless Steel | Stainless Steel 303 | Stainless Steel 304 | Stainless Steel 316 | Stainless Steel 316L | Stainless Steel 420 | Stainless Steel 430 | Stainless Steel 17-4PH | Stainless Steel 301 |

| Stainless Steel 321 | - | - | - | - | - | - | - | |

| Alloy Steel | Q235 (A3 Steel) | 45 Steel | Cr12 | 3Cr13 | GCr15 | 40Cr | Spring Steel 65Mn | Mold Steel SKD11 |

| Copper Alloy | Brass H59 | Brass H62 | Copper T2 | Oxygen-Free Copper TU2 | Tin Bronze QSn-6-6-3 | Beryllium Copper C17200 | - | - |

| Other Alloys | Electrical Pure Iron DT4C | Electrical Pure Iron DT4E | Titanium Alloy TC4 | Magnesium Alloy AZ91D | - | - | - | - |

| Plastics | Engineering Plastic ABS | Polytetrafluoroethylene PTFE | Delrin POM | Phenolic Board | Acrylic PMMA | Polypropylene PP | Polyphenylene Sulfide PPS | Polyurethane PU (Loctite Glue) |

| Polyvinyl Chloride PVC | Epoxy Board FR4 | High-Density Polyethylene HDPE | Low-Density Polyethylene LDPE | Nylon PA6 | Nylon PA66 | Polycarbonate PC | Polyetheretherketone PEEK | |

| Special Materials and Others | Carbon Fiber Board | Graphite | - | - | - | - | - | - |

CNC machining, short for Computer Numerical Control machining, refers to the control of machines by a set of commands issued by a controller. The commands issued by the controller are typically in the form of a list of coordinates, known as G-code. Any machine controlled by such codes can be referred to as a CNC machine, including milling machines, lathes, and even plasma cutters.

The movement of CNC machines can be defined by their axes, including the X-axis, Y-axis, and Z-axis, with more advanced machines also incorporating the A-axis, B-axis, and C-axis. The X-axis, Y-axis, and Z-axis represent the primary Cartesian vectors, while the A-axis, B-axis, and C-axis represent rotational axes. CNC machines typically utilize up to 5 axes.

Upload your 3D file to instantly receive the best price

Your data is kept strictly confidential.